|

Camshaft Lobe Center Measuring |

||

|

|

|

|

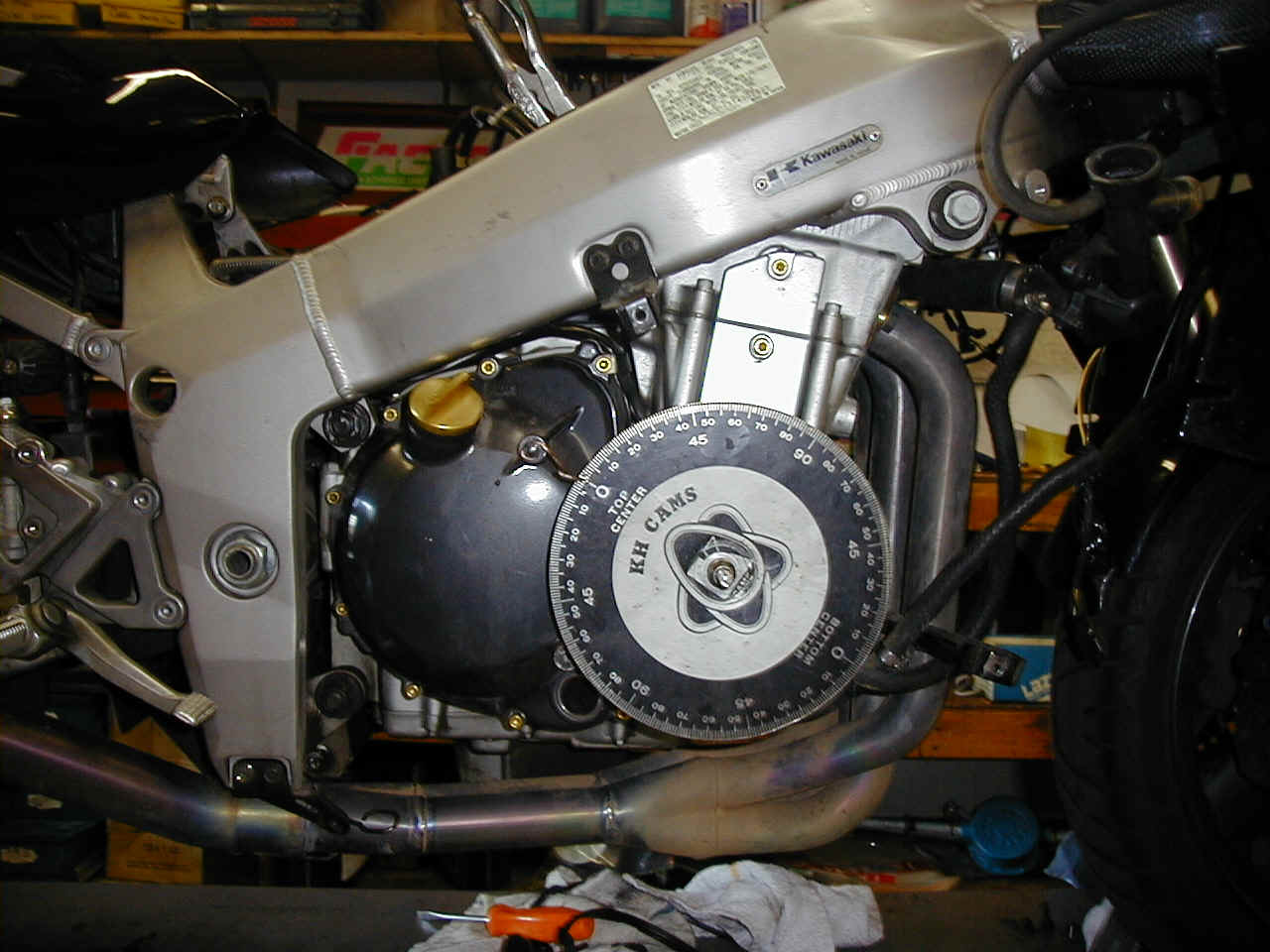

Install your TDC Dial Indicator with special holder installed into spark plug hole. This shows a 2" travel Dial Indicator installed in the #4 cylinder. Note: Degree wheels slip on their adapters and pointers

get bent! You can use a dial indicator on an engine that has a vertical

spark plug hole. For other types of engines with angled spark plug

holes, you will need to use a "positive stop" procedure instead

of a dial indicator. Most Japanese 4 or 5 valve sportbikes have

vertical spark plug holes. |

|

|

Install your 1" travel Valve Travel Dial Indicator with special tip installed. This shows the 1" Dial Indicator installed on the #1 cylinder's intake. If you use cylinder #1 or #4 for TDC, you can use either

cylinder #1 or #4 for Valve Lift. Special tips? They are flexible and point around corners. To make: |

|

|

Measure and calculate Intake Cam Lobe Center setting. Generally, when referencing and optimizing the same set of cams, you will use the Lobe Center method for measuring cam location as referenced to crankshaft location. Rotate the crankshaft in normal engine direction. If the measured intake opening at .040" is after TDC, restart measurement and use .030" or .020" lift. Make sure that you use your selected lift for all measurements on this project. Differences in L.C. numbers are (generally) minimal at .010" to .050" lift on shim and bucket motors but it's best to not gamble with accuracy. After you do intake opening, next record intake closing (at the same lift number). That's where you find out what the little "overall travel" dial on the dial indicator is good for. Check and make a note at where the "little dial" is when the intake valve is fully closed. You may just decide to reset the indicator so that the overall travel is at 0 with the valve fully closed and start over on the intake opening again! Record: Take Total Duration, divide it by 2 (2 is a constant) When done, recheck your TDC / degree wheel setting. If wrong, reset and redo your Lobe Center measurements. (If you are using the TDC Indicator, you would have checked your TDC / degree wheel settings throughout your previous set of valve lift measurements) You have your Intake Lobe Center Lobe Center (AKA L.C.), Method works well when you are comparing the same cam set only. If you were using a different cam duration or lift, the optimum L.C. for one type of cam will NOT be the same as the different cam. |

.040" lift, Intake open (IO)=

Divide Total Duration

Subtract IO from |

+__________

Total Duration/2

(Total Duration/2) - =__________ L.C. Intake |

| For Exhaust Cam: Repeat. The only difference is that you will subtract the Exhaust Valve Closing Lift measurement instead of the Opening (as you did on the intake cam) measurement. The number that you use will, like the Intake Cam measurement, will be the "smaller" of the 2 measured opening numbers. You could say: Also, the exhaust cam is typically more difficult to setup the Valve Lift Indicator on when setting and testing in the frame. You may have to rebend the extended indicator tip. |

||

| Now! Example: The intake valve Intake Opens at 25 degrees Before Top Dead Center (BTDC) - then the piston travels 180 degrees to Bottom Dead Center (BDC), then the piston travels UP, on the compression stroke and at 55 degrees after BDC. Add up all those numbers. 25 + 180 + 55. Write it down! Now - divide that 260 by 2. That's 130. Now, finally, subtract the "smaller number", in this case, 25. You'll get 105 for a lobe center number. . |

||

| . | . | |

| . | . | |

Remember! These are hints only. You are responsible for whatever you do with this information.

If you use this information and it helps your application, please contact Factory Pro with results. Thanks, Marc